| Orig. Posting Date | User Name | Edit Date |

| Mar 5, 2013 06:18PM | DRMINI | |

| Mar 5, 2013 05:33PM | Air2air | Edited: Mar 5, 2013 05:37PM |

| Mar 5, 2013 03:53PM | DRMINI | |

| Mar 5, 2013 10:35AM | Air2air | |

| Mar 4, 2013 09:55PM | DRMINI | |

| Feb 5, 2013 09:06AM | CooperTune | |

| Feb 5, 2013 08:06AM | mur | |

| Feb 5, 2013 12:28AM | DRMINI | Edited: Feb 5, 2013 01:27PM |

| Feb 4, 2013 10:07PM | Motormay1969 | |

| Jan 25, 2013 05:59AM | CooperTune | |

| Jan 23, 2013 07:13PM | 1963SV2 | |

| Jan 23, 2013 06:52PM | Air2air | |

| Jan 23, 2013 05:53PM | DRMINI | Edited: Jan 23, 2013 08:02PM |

| Jan 22, 2013 03:26AM | Motormay1969 | |

| Jan 21, 2013 10:10PM | Spank | |

| Jan 21, 2013 09:20PM | DRMINI | Edited: Jan 22, 2013 02:11PM |

| Jan 21, 2013 08:09PM | GaryE | |

| Jan 21, 2013 04:27PM | 66Cooper'S | Edited: Jan 21, 2013 05:09PM |

| Jan 21, 2013 12:57PM | Spitz | |

| Jan 21, 2013 12:57PM | bluepiper151 |

Found 27 Messages

|

Total posts: 8645

Last post: Dec 16, 2020 Member since:Oct 27, 2000

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

|

I think the idea that big rockers rob you of torque is a bit overdone.

We just engine dynoed a fresh rebuild 1330 with an RE13 Russell Eng cam, Minispares 1.5 `forged/cast' rockers, 12G940 head with Mk2S inlets & unleaded seats, minor port work, and 10.5:1 C/R. It has twin HS4s and a Maniflow med bore LCB + 1-3/4 exhaust system.

Torque.. it made 92.8 lb/ft @ 3500, and 97 @ 4000-4500, 96 @ 5000-5500. That's pretty flat...

HP peak is 107.3 @6500.

Motor is going in a gravel rally car, it may get a 45DCOE Weber later.

Kevin G

1360 power- Morris 1300 auto block, S crank & rods, Russell Engineering RE282 sprint cam, over 125HP at crank, 86.6HP at the wheels @7000+.

|

Total posts: 1557

Last post: Sep 26, 2016 Member since:Nov 24, 2012

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

So Kevin you salvaged them by swapping the adjusters for Rovers. It sounds like I could go ahead and get the purple ones and not feel too bad then, just order Rover adjusters also.

Yes, what you say about the spacers I read a number of other places as well. They bind, never are 100% centered.

Also picked up the tidbit about moving the feeler gauge from left to right instead of in and out, I've gone years without knowing that.

This whole idea is becoming clouded from all the guys who say it will just move power farther up the band and sometimes even take away a little at the bottom. Guess I need to read more raves about it.

|

Total posts: 8645

Last post: Dec 16, 2020 Member since:Oct 27, 2000

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

|

Kevin you're talking about the C-AHT446A purple ones right? I was about to get those. On the UK forums they sell quite a lot of them for what it's worth.

My understanding is that roller-tip only = best, as rollers on the shaft will wear? And are the posts aluminum? Calver says those will squash...urgh.

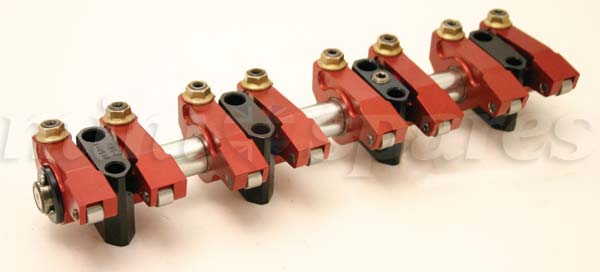

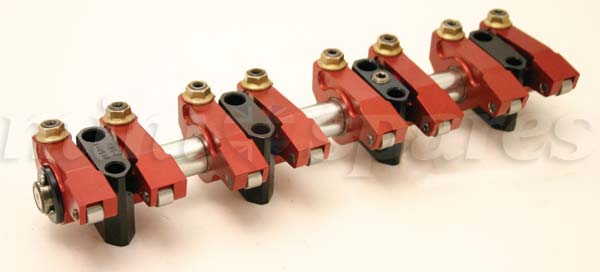

Read a few places that springs on the shaft are preferable to bushes because they won't wear and allow lateral movement of the arm along the shaft. However, the Titans have bushes, at 3x the cost:

Yes, it's the 1.5:1 roller tip purple ones. The posts are STEEL, not alloy. They look well made but the adjusters & nuts are rubbish.

Nothing wrong with the spacer springs for a road car.

I have fitted a few sets of Minisport ones (1.3:1) which have the spacers, in both sets the spacers needed machining or shimming. Because some rockers were jammed, and some too loose.

Swiftune's 1.5 roller tip rockers look nice but are unbushed, the alloy rocker runs on the bigger (17mm) shaft. Anybody used these?

Kevin G

1360 power- Morris 1300 auto block, S crank & rods, Russell Engineering RE282 sprint cam, over 125HP at crank, 86.6HP at the wheels @7000+.

|

Total posts: 1557

Last post: Sep 26, 2016 Member since:Nov 24, 2012

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

Kevin you're talking about the C-AHT446A purple ones right? I was about to get those. On the UK forums they sell quite a lot of them for what it's worth.

My understanding is that roller-tip only = best, as rollers on the shaft will wear? And are the posts aluminum? Calver says those will squash...urgh.

Read a few places that springs on the shaft are preferable to bushes because they won't wear and allow lateral movement of the arm along the shaft. However, the Titans have bushes, at 3x the cost:

|

Total posts: 8645

Last post: Dec 16, 2020 Member since:Oct 27, 2000

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

|

A friend just got a new set of Minispares 1.5 roller tip rockers from UK. 6 of the 8 adjusters were bent (same crap part as their `forged' 1.5s apparently). And likewise, all 8 nuts had only about 50% thread engagement on them. You could rattle em around, typical asian quality.

We binned all the adjusters and fitted some s/h A+ ones and nuts instead. At least Rover made theirs straight...

Kevin G

1360 power- Morris 1300 auto block, S crank & rods, Russell Engineering RE282 sprint cam, over 125HP at crank, 86.6HP at the wheels @7000+.

|

Total posts: 4134

Last post: Oct 13, 2020 Member since:Oct 8, 2011

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

|

I traded for a NOS KD set a couple of years back. I have not used them yet. I wonder what Rockwell numbers I should look for if I have them tested. I can send out for heat treatment and be sure. Steve (CTR)

|

Total posts: 5840

Last post: Nov 1, 2019 Member since:Nov 12, 1999

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

|

I had a set of the soft KD rockers. They did one mini meet road trip and were toast. Like anything, it took quite a while and a fair bit of talking to some pretty smart people to understand what had happened.

The rest of the engine got stock spridget valve springs and a 997 Cooper profile regrind cam and went quite well for years.

|

Total posts: 8645

Last post: Dec 16, 2020 Member since:Oct 27, 2000

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

|

Thank you for that info.

This set I just tested are of the last type, imported from Minispares last month.

I run a set of earlier Minispares 1.5s on my 1360, I don't think they have `Keith Dodd' or `1.5' marked on them, I will check them and take a pic tomorrow.

This set has now done over 50,000 road miles and a few track days. Despite wearing out a VP3 (Oz made) cam the pads still look good and the bushes & shaft seem unworn. So yeah, they used to be a good setup.

[edit] This set (fitted in June, 2001) is not marked Keith Dodds but yes, they are marked 1.5 on one side and some batch? number on the other. They appear to be forged not cast, and the rocker top face is machined square to the threads, unlike the latest set.

Kevin G

1360 power- Morris 1300 auto block, S crank & rods, Russell Engineering RE282 sprint cam, over 125HP at crank, 86.6HP at the wheels @7000+.

|

Total posts: 7

Last post: May 7, 2013 Member since:Dec 25, 2012

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

Ahhhh....science.

This is another case where a bit of measuring and comparison of the measured results paints a much better picture than words alone could. That said, following (below) are a few words on some of the history of 1.5 rockers as sold by the usual UK suspects.

Thanks to the ever-helpful DRMINI(of Oz) for his data and comments posted on this thread.

One of the earliest 1.5 rockers is the original 1.5:1 MSC rocker, designed by Keith Calver in the early 1980s. This was an investment cast component, was very accurate, gave the correct lift ratio, and was hard wearing. It had 'KEITH DODD' (owner of Mini Spares Center) cast in to it.

Sometime later, another rocker came appeared as the replacement for the previous one when the casting company that was making them got in to financial issues, packed up everything and moved without leaving any contact details. They took the tooling with them. As a result, Keith Calver designed a new rocker from experiences learned with the first rocker. This one was even better, except there was a batch made with insufficient heat treatment on the pad that caused premature wear. This was also an investment cast component and had 'KEITH DODD' cast in to it as well. It was distinguishable by the very different 'hooked beak' profile at the pad end.

Following that rocker in history is its replacement which came along when the tooling being used had worn out, so it was decided to do forged instead of casting. Manufactured in the UK by one of the foremost automotive specialist manufacturers, it was heavier than the previous two but proved 100% reliable and gave the required 1.5:1 ratio. It was decided to forge the rocker in this design so it could be used in historic motorsports series where non-roller rockers had to be used. The forging finish was left as forged so that to the untrained eye they look like the original 'S' type rocker. It had 1.5-1 forged in to the side of it.

The latest offering is sourced outside the UK. It is supposed to be a copy of the original forged 1.5:1 rocker, but is nowhere near the quality. Problems are inconsistently drilled/tapped adjuster screw threaded hole, adjuster lock nut land not machined square to the threaded hole, rocker pad does not sit square on the valve tip, ratio all over the place (generally around 1.6 - 1.62:1 on modded engines). Identified by having just 1.5 forged in to the side, and the pads are very smooth/polished.

|

Total posts: 4134

Last post: Oct 13, 2020 Member since:Oct 8, 2011

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

|

I was excited when I found the KD rockers were avalible from Mini Spares Center. I ordered two sets and was very unhappy with what I got. I agree they seem more cast than forged. I had to move them all over the place to get them to line up with valves and shimmed till I got something like a fit. I have three sets of KD rockers with his name ( cast ) into them. One set is still new ( should say NOS ) the other two sets are hammered. I'd consider rebushing and profiling the pads along with hardening.

While chatting with Nick Swift he expressed concern with rockers on the market, his solution was having his own made I have a couple of sets and they are the real deal. Steve (VTR)

|

Total posts: 1716

Last post: Oct 18, 2020 Member since:Oct 18, 2011

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

I did not find high lift rockers to be that useful. I am told that adding 1.5 rockers has a similar effect to moving up "one" cam - ie trading a 276 for a 286. In my case I broke an adjuster on my 1.5 Titan RRs (the tacho showed 10K just as I reached the ignition key) - broken throttle cables and 8lb flywheels are not compatible..

Anyway, I replaced the RRs with a set of standard S rockers which made a noticeable improvement at commuting speeds - although maybe it doesn't rev quite as well ???. As I suggested on another thread - I would be saving up for an improved head before spending money on high lift rockers...

Cheers, Ian

|

Total posts: 1557

Last post: Sep 26, 2016 Member since:Nov 24, 2012

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

Like I said above I'm seriously considering it as a first step to stage 2. Right now I have:

Mk1 A+ 1275 with new rods, mains, trans. From an AA.

HS4, Cooper freeflow, Pertronix. Daily driver.

...I can only spend a few hundred a month. Is this a logical baby step?

|

Total posts: 8645

Last post: Dec 16, 2020 Member since:Oct 27, 2000

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

|

Further to my investigations of the currently available C-AHT436 rocker set:

1. 7 of the 8 adjuster screws were not straight. The ball end was orbiting when the adjuster was rotated.

2. When replaced with A+ adjusters and nuts, the nuts were not sitting square on the rocker, the rocker face was off square by up to 3°. I have machined them square. I noted that the material turns like cast iron, not forged steel... but I found the rocker pads are hardened, as they should be.

3. Valve lifts all measured at #1 exhaust valve, with A+ adjusters now:

Rocker numbers:

#1 ex was .416" now .419"

#2 ex was .430" now .424"

#3 ex was .435" now .425"

#4 ex was .438" now .432"

#1 inlet was .428" now .431"

#2 inlet was .426" now .433"

#3 inlet was .424" now .424"

#4 inlet was .415" now .430"

[edit] I will swap #4 exhaust rocker with #3 inlet one.

Comment: They are worth using now, but not as received from UK.

IMO unless you are prepared to mess about with checking & rectifying these `forged' (I reckon are cast iron) rockers as I did, I'd save your $$$ and buy roller tip ones instead.

Kevin G

1360 power- Morris 1300 auto block, S crank & rods, Russell Engineering RE282 sprint cam, over 125HP at crank, 86.6HP at the wheels @7000+.

|

Total posts: 7

Last post: May 7, 2013 Member since:Dec 25, 2012

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

I would suggest that you already have an engine spec way beyond the capability of the standard ECU to make proper use of. Adding 1.5 ratio rockers will not help much at all. And if the engine doesn't already run a little roughly, adding the 1.5 ratio rockers will. The 276 cam has an LCA of 106 degrees, somewhat too narrow for the standard injection to deal with effectively as there is too much over-lap at TDC. Most A-series injection cams have LCAs of 110 to 112 deg to dramatically reduce overlap at TDC. Extended over-lap causes more fuel to exist in the exhaust gas, which the ECU will harrass itself over trying to compensate for it.

As far as a standard SPi or MPi engine goes, using 1.5 ratio rockers on the standard spec cam along with a modified head helps, as it is the cam spec that governs overlap at TDC, not the rockers. Excepting, of course, how far they are open at that point. Whether they should be used with a cam developed for the injection engines depends on whether that cam profile was developed to use the higher lift rockers.

|

Total posts: 6349

Last post: Oct 22, 2023 Member since:Mar 9, 1999

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

|

I have at least one set of 1.5 rockers with Dodd cast into them and the faces are hammered as in heavily dimpled. Doesn't look like the pads were hardened at all, or if they were they were installed on a head where each and every valve guide either seized or made contact with the piston below.

I've also got a very used take-off set that I mounted on the LeMons moke with a 285 reground cam ("old skool" low lift) and they have held up fine over 70 hours or racing with somewhat properly set up springs (not oversprung, anyway). I've never checked their lift figures, though.

|

Total posts: 8645

Last post: Dec 16, 2020 Member since:Oct 27, 2000

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

|

I have just fitted a set of these 1.5 forged rockers to a 1330 I'm building.

I had been told that the rocker ratio on recent ones was all over the place, whereas the original Keith Dodd ones were pretty good.

So, today I put the dial gauge on them to check lift.

Cam is a fresh Graham Russell RE13 (.290" lift at lobe), with new lifters, pushrods and brand new C-AHT436 forged rockers. Valves are all new, with new unleaded seats, so valve stem heights between cylinders are the same.

Valve lift figures were taken with .019" rocker clearance:

#1 ex = .416"

#2 ex = .430"

#3 ex = .435"

#4 ex = .438"

#1 inlet = .428"

#2 inlet = .426"

#3 inlet = .424"

#4 inlet = .415"

I've not sussed out yet what the problem is, but I suspect it's in the adjusting screw & locknut area. The nuts are not seating square on the tops of the rockers......

[edit 1] I have a set of the Keith Dodd forged originals on my 1360, after 50,000 miles there's no wear on valve stems or the bronze guides when I had it apart for a freshen up recently.

[edit 2] Today I removed the #1 exhaust rocker which had .416" lift, and measured the adjusters and nuts.

Adjusters are .020" undersized, but the thread tapped in the rocker seems on size when I screwed an A+ adjuster into it. The chinese nuts are loose (as usual), even when put on the A+ adjuster.

I refitted the #1 exhaust rocker, with an A+ adjuster and nut, set it to .019" clearance and the lift only went up to .419". I gained .003".

What I will do now is remove the rocker assembly, fit A+ adjusters & nuts to all, then set the shaft up on the head with NO rockers on, and try the lift of each rocker in turn at the #1 exhaust position (easy to fit and remove them from there).

If the lifts still have a lot of variance I will swap them about so the 4 highest lift ones are on the inlet valves.

Not much else I can do, unless Graham can re-profile the pads relative to the shaft centre to make them the same.

BTW all the bushes are a good fit on the shaft, they are not loose.

Kevin G

1360 power- Morris 1300 auto block, S crank & rods, Russell Engineering RE282 sprint cam, over 125HP at crank, 86.6HP at the wheels @7000+.

|

Total posts: 137

Last post: Mar 23, 2016 Member since:Apr 26, 2012

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

|

Disclaimer: I do not have any experience with Mini engines.

Ratio'd rockers (cast or forged) on extremely modified VW engines (of which I have lots of experience), well, even stock engines, will be hard on valves and valve guides as they put more side pressure on the valve stem than stock ratio rockers. As result, using roller rockers is necessary. I have considered a set of ratio rockers for the Cooper here, but if I do, it will be one of the roller rocker sets offered. Unfortunately, the good set with the needle bearings is quite pricey, so I may consider the bronze bushing roller set instead. But, I will definitely not go with the forged set, unless I learn that valve stem side load is not a concern on the Mini engine.

|

Total posts: 3523

Last post: Jul 9, 2023 Member since:Feb 26, 1999

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

|

As you are asking about the 1.5:1 "Keith Dodd" rockers They are a very good set to have. I'll add just make sure you read about "spring crush". Can't address SPI issues - but you asked about the rockers.

//www.minimania.com/part/C-AEA527/Cylinder-Head-Valve-Springs-240lbs-Anti-Bind-570-Lift

|

Total posts: 13978

Last post: Jan 15, 2024 Member since:Jan 22, 2003

|

Cars in Garage: 4

Photos: 381 WorkBench Posts: 1 |

|

Never had them so can't comment on functionality.

From reading however, I'll be saving my pennies for a set of 1.3 roller rockers.

"Everybody should own a MINI at some point, or you are incomplete as a human being" - James May

"WET COOPER", Partsguy1 (Terry Snell of Penticton BC ) - Could you send the money for the unpaid parts and court fees.

Ordered so by a Judge

|

Total posts: 28

Last post: Aug 20, 2014 Member since:Feb 22, 2011

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

|

When I purchased the car I was told that the ECU was remapped..I know there is a limit as to what can be done with the ECU on a SPI car....It does have polished/ported stock head and dual valve springs with stainless steel intake and exhaust valves.

Found 27 Messages