| Orig. Posting Date | User Name | Edit Date |

| Aug 26, 2007 07:04PM | S&M Minis | Edited: Aug 26, 2007 09:16PM |

| Aug 12, 2007 12:56PM | Scargo | |

| Aug 10, 2007 03:47PM | mysteryminimaven | |

| Aug 10, 2007 03:28PM | Scargo | |

| Jun 16, 2007 04:53PM | Rabbit527 | |

| Jun 16, 2007 03:51PM | MacDhaibhidh | |

| Jun 16, 2007 02:19AM | panthersteve | |

| May 3, 2007 04:40PM | theminimark | |

| May 2, 2007 10:36AM | MacDhaibhidh | |

| Apr 28, 2007 07:27PM | S&M Minis | |

| Apr 25, 2007 10:54AM | Tulka | Edited: Apr 25, 2007 10:57AM |

| Apr 19, 2007 08:24AM | Tulka | |

| Mar 19, 2007 02:07PM | Tulka | Edited: Mar 19, 2007 02:11PM |

| Mar 12, 2007 12:51PM | S&M Minis | |

| Mar 12, 2007 12:45PM | Tulka | |

| Mar 12, 2007 12:24PM | S&M Minis | |

| Mar 12, 2007 11:48AM | Tulka | Edited: Mar 12, 2007 11:56AM |

| Mar 9, 2007 02:10PM | Tulka | |

| Mar 3, 2007 08:48AM | Cheleker | |

| Mar 3, 2007 08:37AM | S&M Minis |

|

Total posts:

Last post: Member since:

|

|

My thanks to Scargo for letting me know there was some recent activity on this thread, and my apologies to everyone for starting it and then stepping away for a few months. Due to work demands (have to pay those bills), the racing season (have to create more bills), and a few summer construction projects (yet more bills) I had to completely avoid the message board for awhile.

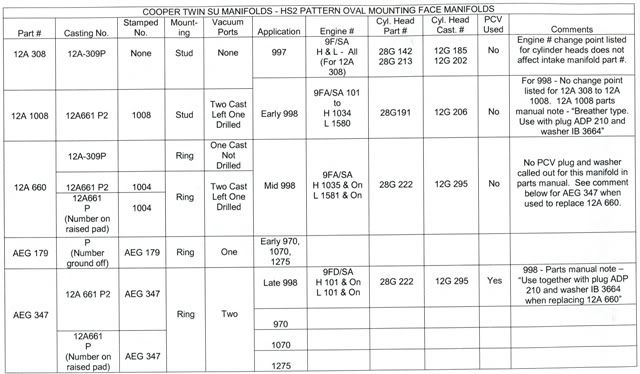

I did start researching the BMC parts manuals to match up manifolds to engine numbers, as well as trying to definitively match manifold pictures submitted on this thread to parts numbers in those manuals. Here’s some progress on the 997 and 998 engines, possibly the most difficult due to the number of changes in the entire Cooper and S line during their production period. It would appear that BMC was trying to standardize manifolds across the S and non-S lines while simultaneously maintaining the parts number trail for homologation purposes. Capturing this in an easily understandable format has been a bit of a challenge; hopefully the updated chart is a step in the right direction. (My current work projects are unfortunately very similar to this “fun” project – taking boxes of environmental and safety documents and sorting and charting them into an understandable format while interpreting all the OSHA and EPA regulations applying to them. Kind of takes the edge off doing the “fun” project after work. At least with the “fun” project no one goes to prison if I get it wrong!)

Note that conflicts exist between the notations in the BMC parts manuals and pictures that have been submitted. This is primarily around whether or not the manifolds had vacuum ports cast in and/or drilled. I’m leaning toward going with the photographic evidence if it looks like an unmodified manifold. There’s also a possibility that later versions of the parts manuals would clarify these discrepancies. To sort the manifolds I developed the rule-of-thumb that the brake booster is connected to the vacuum port located above the cylinder 3 and 4 intake tract (right end of the manifold) and the PCV valve is connected to the vacuum port located on the center or left-of-center on the balance log. (Does that match up with everyone’s experience?) Based on this criteria, if there is not a drilled and tapped vacuum port above the right intake tract, it cannot be an S manifold.

Anyway, here’s a revised chart for the manifolds with oval carb mounting faces and HS2 bolt patterns. The data for the S engines is yet to be entered - 997 and 998 data is provided. This may answer the questions from Panthersteve about the 998 engine designations, although I don’t know how closely the Australian cars aligned with this information. Note that early, mid and late is my terminology – it’s not taken from any BMC publications – and it lines up with the three major change points in the production of the 998 Cooper engine as listed in the chart. It’s probably best to bounce back and forth between the chart and the explanations below it. Send me an e-mail if you would like a Word version of this write-up, with pictures embedded it’s a 398KB file.

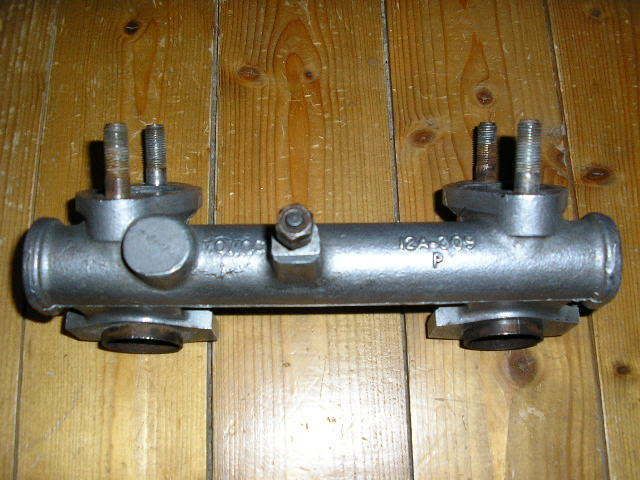

997 – This one is a slam dunk – one intake manifold for the entire production run, the 12A 308. There were two different heads with engine number change points listed in the parts manual. This didn’t affect the manifold, so I haven’t listed the change points on the chart. I have both of these head castings and can detect no difference between them. It’s also interesting to note that the 12G 185 casting is not listed in any of the popular Mini tuning books, at least that I’ve seen. Also note that the casting numbers for any of the Mini cylinder heads are not listed in the parts manuals, only the part numbers are in the parts manuals. I have 12G 185 heads in my fairly extensive 997 collection and have made the assumption it is the earlier part number. The picture below is of the manifold from a 1962 997 Cooper I bought in 1967. (And please take a look at my separate post about that car that I’ll be making later today!)

998 – The “early” engine uses the 12G 206 head casting, the “mid” engine uses the more common 12G 295 head casting, and the “late” engine uses the 295 head and positive crankcase ventilation (PCV). The change points in the parts manual for the cylinder heads and PCV are identical to the change points listed for the intake manifolds. I don’t know if the same change points would apply to the Australian cars, per Panthersteve’s question. Details for each subgroup follow.

998 Early – These engines used the 12G 206 head that has the port and combustion chamber shape of the later 12G 295 head combined with the smaller valves and stud location of the intake manifold of the 997 heads (12G 185 and 12G 202). (Note that the popular Mini tuning books list this head as having the larger intake valve size as the later 295 head, however that is incorrect. The parts manuals list a different intake valve for the 206 head – I have purchased them (long ago) and they are 997 size. I also have two unmodified 206 heads in the collection – 997 size valves there too. Given their rarity of the 206 head the valve size is a moot point.) For intake manifolds this head used either the 12A 308 (same as the 997) or the 12A 1008. Both would need the stud location method to work on the 206 head. There is no engine number change point listed in the parts manual for the two manifolds, so there’s no way to tell how many of each were produced. The entire 206 head range covers 2,614 engine numbers so there weren’t very many of either produced. The manual does list the 12A 1008 manifold as a “Breather Type”, see the comments on the chart. The 12A 308 manifold would presumably be the same as the 997 type pictured above. Two 12A 1008 manifolds are pictured below. They are the “Breather Type” as stated in the parts manual, are based on the 12A 661 P2 casting, and have the number 1008 stamped into them. The vacuum breather port would have been plugged. Note that per the rule-of-thumb stated above these cannot be S manifolds because the brake booster boss is not drilled. A picture of a 12A 1008 manifold based on the 12A 661 P casting has not surfaced yet. The first picture below was provided by Nick Rogers.

The second picture was provided by Tulka and is unusual in having both the ears needed for stud location and the machined groove for ring location. Since it is stamped as a 1008 it is included here as an Early 998 manifold, but it could also have been an “Early” to “Mid” transition part.

998 Mid – For the 12G 295 head used on this engine series the intake manifold changed to the ring locators, actually called ferrules in the parts manual. Based on pictures provided there were three different castings used for the 12A 660 intake manifolds. The first is the 12A-309 P casting with ring location and no vacuum port. This appears to be the original 997 manifold casting with a brake booster boss added but not drilled, and machined for ring mounting. There are no numbers stamped into this one, such as the 1004 on the next two described below. But Mid 998 is the only application it would fit, so that’s where it goes on the chart. It also fits the parts manual inference that the 12A 660 was a non-breather manifold. This one is listed first on the chart for the 12A 660 manifolds; I’m guessing it preceded the two described below due to its 997 casting origins. This casting may also be the basis for the AEG 179 manifold used on early S motors, but more on that later. This picture was also provided by Tulka.

The second and third 12A 660 manifolds are based on the 12A661 P and 12A661 P2 castings. Both have the number 1004 stamped on the balance log and both have the center vacuum port boss drilled out. These cannot be S manifolds as the brake booster boss is not drilled out. As noted in the comments on the chart the parts manual infers that the 12A 660 is a non-breather manifold, which conflicts with the photographic evidence below. Perhaps this was clarified in later “issues” of the parts manual. The first picture is a 12A661 P casting provided by Club Man and the second is a 12A661 P2 casting provided by BW Autosport.

Late 998 – This engine series also used the 12G 295 head but was equipped with PCV. The engine number prefix changed from 9FA to 9FD, and the engine number chart in the front of the BMC parts manual specifically calls out “D” prefix engines as being PCV equipped. The same “D” prefix notation also applied to the S engines equipped with PCV. The AEG 347 intake manifolds used on this 998 engine (And on the S motors produced in the same time frame) was based on the same two castings as described above for the 998 Mid engine, the 12A661 P and 12A661 P2. They are, however, stamped AEG 347 and have both vacuum bosses drilled out. For 998 applications the vacuum boss on the right side is plugged, the one that is used for the brake booster on S applications. At this point standardization had been achieved; all S and non-S engines were using the AEG 347 manifold. It appears that the only way to determine if an AEG 347 was originally on a 998 or one of the S engines is if the carbs are with it. Even if the carb tags are missing, the 998 carbs had a vacuum port for the distributor advance and the S carbs didn’t. (I’m open to supporting or refuting documentation on that piece of information.) The first picture is a 12A661 P casting from my collection. The second picture is a 12A661 P2 casting provided by Bruce Gebbie.

//i118.photobucket.com/albums/o102/prjm3/12A661P2AEG347BruceGebbie2-1.jpg>

That’s where we are so far! Hopefully the pictures are all in the correct places. I have to go back through all of the pictures submitted to see if there are variations I missed, so this description and the chart may evolve further. If not, I’ll start filling in the S data.

Randy McC

|

Total posts:

Last post: Member since:

|

|

|

Total posts:

Last post: Member since:

|

|

Mangoletsi 4011 manifold. English made, the company had a bad reputation for casting flaws and on other manifolds, linkages that were poorly designed. Many were originally painted orange. A 70s-80s relic. Should work fine on your application.

|

Total posts:

Last post: Member since:

|

|

Perhaps you guys on this thread can help identify this 1.5" manifold which I plan to use on a recently built 1293. I have no idea where it originated but it has the correct mounting face for a pair of HS4's, set at the proper 30 degree angle suitable for the Mini application and has the desirable 6" spacing. The only form of identification is the casting mark "4011" shown on top of the balance tube. If anyone recognizes this one and/or knows anything more about it I'd like to hear from you.

|

Total posts:

Last post: Member since:

|

|

Here is a standard HS4...not sure of the casting #

And a modified Maniflow to replace the stock HS4 above...added the brake booster and throttle cable provisions..ground all the awful factory welds and had it ceramic coated....![]()

|

Total posts:

Last post: Member since:

|

|

|

Total posts:

Last post: Member since:

|

|

Hi all,

Just wondering how work on this list is going?

I am really interested in items 1 & 2 on the list and what constitutes early and mid 998?

Also what info is this based on? I have an Australian 998 Cooper which is a midish '65, this is by our standards a late 998, would the manifold fitted have been the same as in other markets? Was pcv fitted to 998 Coopers? If so when from?

I hope there is not too many questions here!!

Cheers Steve

|

Total posts:

Last post: Member since:

|

|

Hey, I've just found another, but it is a C-AEG 489, most likely. It is cast with 12G 2464, and below that has the BSK 2., also cast.

I think that the previous owner plugged the vac port with a threaded brass plug. It's not worthy of photos, just thought to post it.

Best regards,

MSH

|

Total posts:

Last post: Member since:

|

|

|

Total posts:

Last post: Member since:

|

|

Tulka,

I haven't been able to check the message board for a week or so, just saw your latest addition. Where do you find this stuff? Are you having these cast up and/or machined just to confuse us?

Good stuff, keep it up. I have a vacationscheduled for next week, will hopefully make some progress on the article.

RJM

|

Total posts:

Last post: Member since:

|

|

Manifold of the week? Ears are cut a bit for easy mounting but both ring and stud.

Tulka

|

Total posts:

Last post: Member since:

|

|

A picture of stud mounted with non drilled vaccum.

Tulka

|

Total posts:

Last post: Member since:

|

|

For better understanding of the evolution manifold,go back some pages and have a look at the EVO Mini.

Tulka

|

Total posts:

Last post: Member since:

|

|

That's correct, my papers are #5028. They are also the source of the "evolution" manifold picture that I posted previously.

I forgot to mention that the manifold in the homologation picture you posted earlier today probably warrants a new line on the chart. A brake booster tap and stud mounting is a combination not on the chart yet. Do you think those are stud mounts in the picture? If so, I'll add the line to the chart with a lot of blank spaces to be filled.

|

Total posts:

Last post: Member since:

|

|

Your homologation is 1275/no 5028 valid from January 1st -66 and I can see your pictures are as bad as mine.There is also Group 2 1275/no 1300 valid 11th April -64 .So we want better pictures!

Tulka

|

Total posts:

Last post: Member since:

|

|

Tulka,

It's not dead by a long shot! I'm trying to write the article for posting on the Technical Info. page but work is getting in the way.

Your homologation picture throws in a new wrinkle. It would seem likely that the homologation papers would show the current production piece. The only manifold identified so far with a single vacuum port cast and drilled is AEG 179. That's the one with the original casting number ground off and AEG 179 stamped.

But the one in your homologation picture appears to have stud mounting ears on the head face. No pictures of that combination have surfaced yet. Maybe they are 1071 papers that you have - the first S model produced? It also seems that for the number to show up in the picture it would need to be raised rather than stamped. Does anyone have an original 1071 or 970 to compare?

The same problem exists for the 1275 homologation papers. This picture is from the RAC papers for a 1275, equally poor quality. From the shadows it is casting it would appear to have two vacuum ports cast in and the brake booster fitting is installed. The production manifold would be an AEG 347 (either the 'P' or 'P2' casting). Does that look like the number stamped in it with the csat number hidden in the shadow, per the second picture below that was previously posted by Bruce Gebbie?

|

Total posts:

Last post: Member since:

|

|

Think the thread is dead? Now we start with FIA homologation manifolds; This is from a bad copy of a photocopy so the numbers shows badly.I put it upside down to try to read the numbers,anybody have a better picture?I think this one was from the 970.Stud mounted like many in the homologation forms but wih one drilled vaccom port.

Tulka

|

Total posts:

Last post: Member since:

|

|

List of other manifolds needed to?

Tulka

|

Total posts:

Last post: Member since:

|

|

I'll echo a "thanks" from the Mini Community!

Two places to suggest for "peer review."

1. Mini Specialist Forums/Early Mini section. A couple of people that should have already contributed to your listing, Mark Forster and Nick Rogers are frequenters of that Board as well as other very knowledgable people. (If Mark and Nick haven't contributed, yet, let me know and I'll "remind" them!)

2. This is one that should go to the Mini Cooper Register. Most definitely!

|

Total posts:

Last post: Member since:

|

|

All, Please be assured that I will approach our host about posting the final version (not that it might ever be considered final) of this chart and the supporting pictures on the Technical Information page rather than leaving it in a long, unweildy thread.

Dan, Posting the chart on various boards for more of a global input is a worthwhile suggestion. It's not quite at that point yet, still need to do the engine number change points and clean up a few details. I could use input on what the other posting locations might be - which ones will provide a broad audience of knowledgeable participants? Boards in the UK sound like an obvious choice, I just don't know what, where and who they are.

And as long as we are sounding like we're at work, posting to a large knowledgeable audience not only broadens the input, but it also achieves a "peer review". I do technical and scientific publications on occassion, and these are always submitted for peer review by a qualified audience as a quality control process. That's what has been happening on this thread without actually saying so. I've already had to change several preconceptions I had about these manifolds based on hard evidence that came via this thread. The process works and going to a broader audience will improve it further.

Thanks for the input and support.